Foundry

3-Foundries Located within 20Kms radius and equipped with Modern amenities manufactures Super Alloy Steels, Duplex Stainless Steel, Stainless Steel and Carbon Steel Casting for critical applications across industries in exacting specifications.

- Built-up Area - 120,000 sq.ft

- In-house pattern development centre with well trained pattern technicians for timely sample delivery.

- In-house Fettling process.

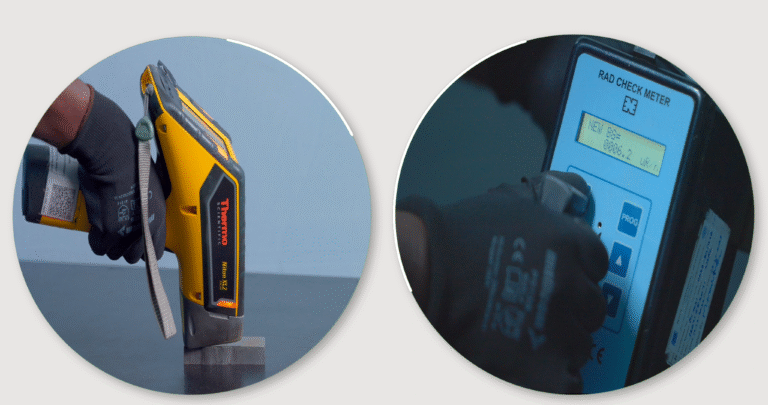

- In-house Testing facilities - Chemical Analysis & Mechanical Testing.

Pattern Shop

- Individual pattern shop in all the 3 foundries

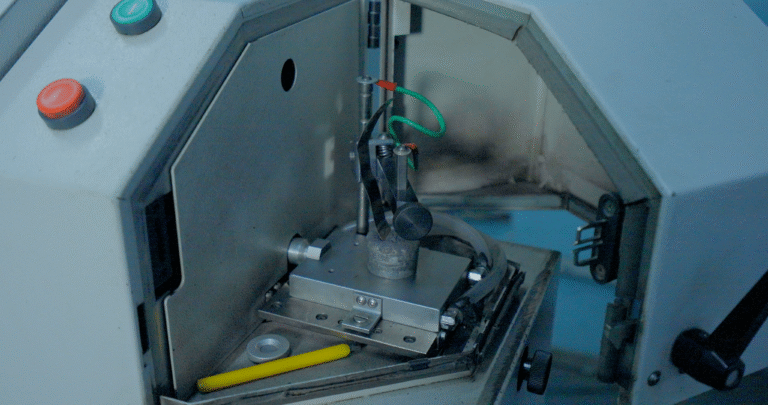

- Magma 6.0 Thermal solidification software

- CNC machine for in-house pattern manufacture

- In-House Facility in all three Units.

- Supported by skilled Sub-Contractors.

- Experienced Team.

- Patterns made in Wood & Aluminum, Cast iron and Gun metal.

- Handling 3000+ Active Patterns.

Furnace Size

- Furnace Type – Electrical Induction.

- Number of Furnaces- 8 crucible with range from 250kgs to 2000kgs.

Foundry Process

Mould making

- Sodium silicate (Na2 Si03+Co2)

- Alphaset (3 Part no bake)

- Shell moulding Process

Core making

- Sodium Silicate / CO2

- Shell core process.

- Alphaset.

Fettling

- Cutting of Runner & Riser

- Arc cutting.

- Gas cutting.

- By Grinding.

- Full-fledged Fettling.

- Dressing facility- Steel Shot Blaster.

- Qualified Welders.

Heat Treatment

- Electrical heat treatment Furnaces.

- Water quenching tanks.